Zenput, the global leader in operations execution solutions, today announced the introduction of the Zenput Connected Store, which integrates in-store IoT devices with the company’s core platform.

Connected Store offering includes new capabilities for automated temperature monitoring

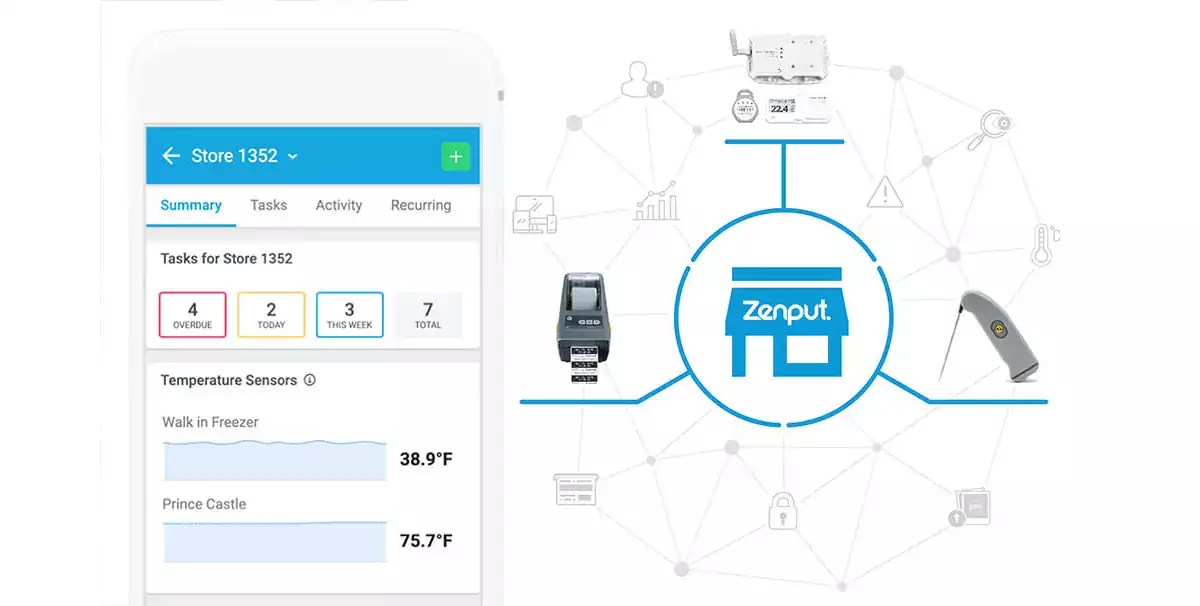

San Francisco, Calif. - Oct. 2, 2019 -- Zenput, the global leader in operations execution solutions, today announced the introduction of the Zenput Connected Store, which integrates in-store IoT devices with the company’s core platform. The expanded offering includes Zenput Temp Monitoring which feeds signals from temperature sensor devices into Zenput and gives multi-unit operators real-time visibility into food safety conditions.

“Every day, we have field and store employees feeding more than 1.3 million updates into our core platform about task completion, food safety procedures, compliance with brand standards and more across tens of thousands of stores,” said Zenput CEO Vladik Rikhter. “With our Connected Store initiative, we’re now capturing a range of additional signals from across a brand’s operation to improve employee productivity and help ops leaders stay a step ahead of potential issues.”

The Zenput Connected Store makes available to customers of Zenput’s core operations execution platform a range of capabilities:

- Zenput Temp Monitoring automatically logs temperatures of make lines, walk-in coolers, and other equipment, and alerts staff or management if they go out of range

- Zenput Labels ensures that every store is using food labels with the correct expiration dates, and that employees can easily print them in seconds

- Bluetooth Thermometer Sync enables staff to use probes to automatically capture temperatures of food in their Zenput forms via bluetooth connection

“Zenput gives us a complete, centralized view of what happens and needs to happen in every store every day,” said Gary George, director of operations for MM Subs, a Jersey Mike’s franchisee. “Now with the ability to automatically monitor and receive alerts for our equipment temperatures, we’re reducing the risk of product being spoiled while freeing up staff to refocus their time on other work.”

“Zenput has increased our confidence in food safety practices and record keeping across all of our stores,” said Stephanie Siegwald, operations development director at RPM Pizza, Domino’s largest franchisee in the U.S. “A critical aspect of that is Zenput Labels, which automates and makes it easy to print critical dates and details at every step of our food preparation process.”

For more information on the Zenput Connected Store, join the webinar on October 22, 2019 at 10am PT / 1pm ET; register here.

—

About Zenput

Zenput is how top operators elevate team execution in every store. Restaurant, retail, and other multi-unit operators such as Chipotle, Domino's, and 7-Eleven use the platform to automate how operating procedures and key initiatives are rolled-out and enforced. Supporting 40,000 locations in over 35 countries, Zenput makes every field and store employee more productive and better equipped to do their jobs well. For more information, visit zenput.com.