Internet of Things (IoT) is the next phase in the digital transformation revolution. While there are many facets to what IoT can encompass as a space, specifically for restaurants, convenience stores, and supermarkets, IoT can have the highest impact by providing real-time temperature monitoring.

Simply put, IoT is connecting devices to the web, whether that’s a walk-in freezer or a standalone temperature sensor, connecting equipment to the internet presents a world of opportunity.

At first glance, IoT may come across as one of those trendy tech buzzwords but given its tenure, IoT has had the time to mature to the point where it possesses two very important attributes: 1) affordability and 2) real-world value in the now and not in some near, promised future. This means that in a relatively short time period IoT devices will no longer be considered cutting edge, and rather a minimum basic requirement.

The New Possibilities of IoT

Monitoring temperatures via IoT devices can help restaurant, convenience store, and supermarket operators protect their employees, customers, and overall businesses by flagging potentially hazardous events from occurring or worsening. Let’s take a closer look into the business impacts of IoT and some potential operations scenarios.

First, IoT devices give operators the ability to take proactive action when something happens that shouldn’t.

- Temperature Monitoring without IoT Devices: You open your store Monday morning to discover that an equipment failure caused everything in your freezer to go bad. Yikes. Now you need new equipment and new inventory before you can serve customers.

- Temperature Monitoring with IoT Devices: An alert pops up on your phone telling you the temperature of your freezer was out of range and trending towards an incident. You contact maintenance or visit the store and discover the freezer is broken. You are able to save thousands in inventory.

Secondly, IoT equipment provides operators with access to real-time data from anywhere, at any time. Having a continuous 24/7 temperature log allows for less time spent manually collecting that data throughout the day, and better and more complete logs. As a bonus, you can use your temperature logs for future negotiations with corporate or with vendors to prove they need to maintain or replace equipment (at their cost).

- Temperature Monitoring without IoT Devices: A surplus of food was prepared during the day and there are leftovers that need to be refrigerated and saved for the next day’s use. It’s almost store close, and your employees don’t have time to follow the full 2-hour FDA cool down process, so they put the leftovers in the fridge and don't check the temperature or write it down until the morning shift. The food cooled down too slowly in the fridge and bacteria grew overnight, unfortunately making some of your customers sick the next day. You are now on the hook for providing “proof of innocence” to the auditor who’s been assigned to the case, but don’t have the means to do so.

- Temperature Monitoring with IoT Devices: When a customer calls to complain about a potential health incident, you instantly log on to your mobile device and check the temperature log for cold/hot holding equipment during the customer’s visit. You find complete logs in realtime at your fingertips, proving that all equipment was at the proper temperatures and all leftover food was stored according to proper protocols, eliminating your store as the source of the health incident.

Third, operators can draw insights from the data to make smarter business decisions

- Temperature Monitoring without IoT Devices: Unbeknownst to you, deliveries are causing the freezer’s doors to be propped open for too long, causing unsafe temperatures, quality problems, and certain items to spoil faster than they should be.

- Temperature Monitoring with IoT Devices: After analyzing your temperature monitoring data, you notice a red flag and take immediate corrective action to stop it from occurring in the future. You have a conversation with your delivery vendors and retrain your employees to avoid food product spoilage or degradation.

To ensure you always end up in that best-case scenario it’s important to first have a basic understanding of the three components of IoT devices:

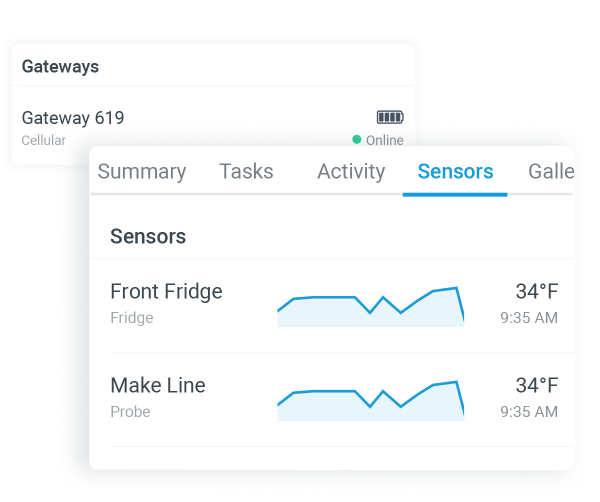

- Hardware: Sensors (or other equipment with integrated sensors). IoT sensors are commoditized, meaning that the technology has matured to the point that it’s relatively inexpensive and is similar across vendors and solutions. Quality sensor hardware devices are easy for each store to set up, wireless with long-range functionality, and last for years.

Something to look out for: overly expensive or drastically underpriced hardware - both should raise red flags. Most sensors should fall within the same cost-range, making a high price tag very suspicious, while cheap hardware is probably cheap for a reason.

- Software: Web-based and mobile applications. Software is the biggest differentiating factor when it comes to IoT solutions. That’s because it will dictate how you interact with your IoT devices, the insights you get, the reliability and utility of your alerts and insights.

- Network Connection: How the hardware talks to the software. There are two schools of thought when it comes to network protocols and device management, proprietary and open source.

Many vendors come up with their own networking protocols, meaning that it’s proprietary to them and your sensors must use their software permanently. In contrast, open-source protocols offer you the advantage of allowing your hardware to work with many different vendors. So, if your vendor is having issues or perhaps goes out of business in the future, you have a new vendor install their software on your preexisting sensors.

Ultimately, your decision comes down to whether or not you prefer a proprietary or open-source network connection between your hardware and software devices.

How to Start Your IoT Journey for Temperature Monitoring

You might be sold on IoT temperature monitoring because it can save you tens of thousands in inventory loss or because it frees up your employees’ time to work on higher-value activities, but it’s a brave new world and can be intimidating to navigate at the start. Here are some simple steps you can begin with:

- Research best-in-class vendors and work on identifying the vendor you want to work with.

- Launch a small pilot in one or two stores to validate that the selected vendor’s hardware and software are up to the task.

- Simulate equipment failure to test the sensor’s alert system.

Watch the video below to see how Dominos protects their inventory and their customers through automation and connected IoT devices:

Subscribe to our blog

You are now subscribed!